Hydraulic Pump Coupling Types . everything you need to know about pump couplings: 4.2 types of rigid couplings. pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 44 4.2.2 flanged adjustable and flanged adjustable with. so, what are the different types of pump coupling and when should they be used? the key function of a pump coupling is to efficiently transfer mechanical power from the power source (motor or engine) to the hydraulic pump. where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy. as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump.

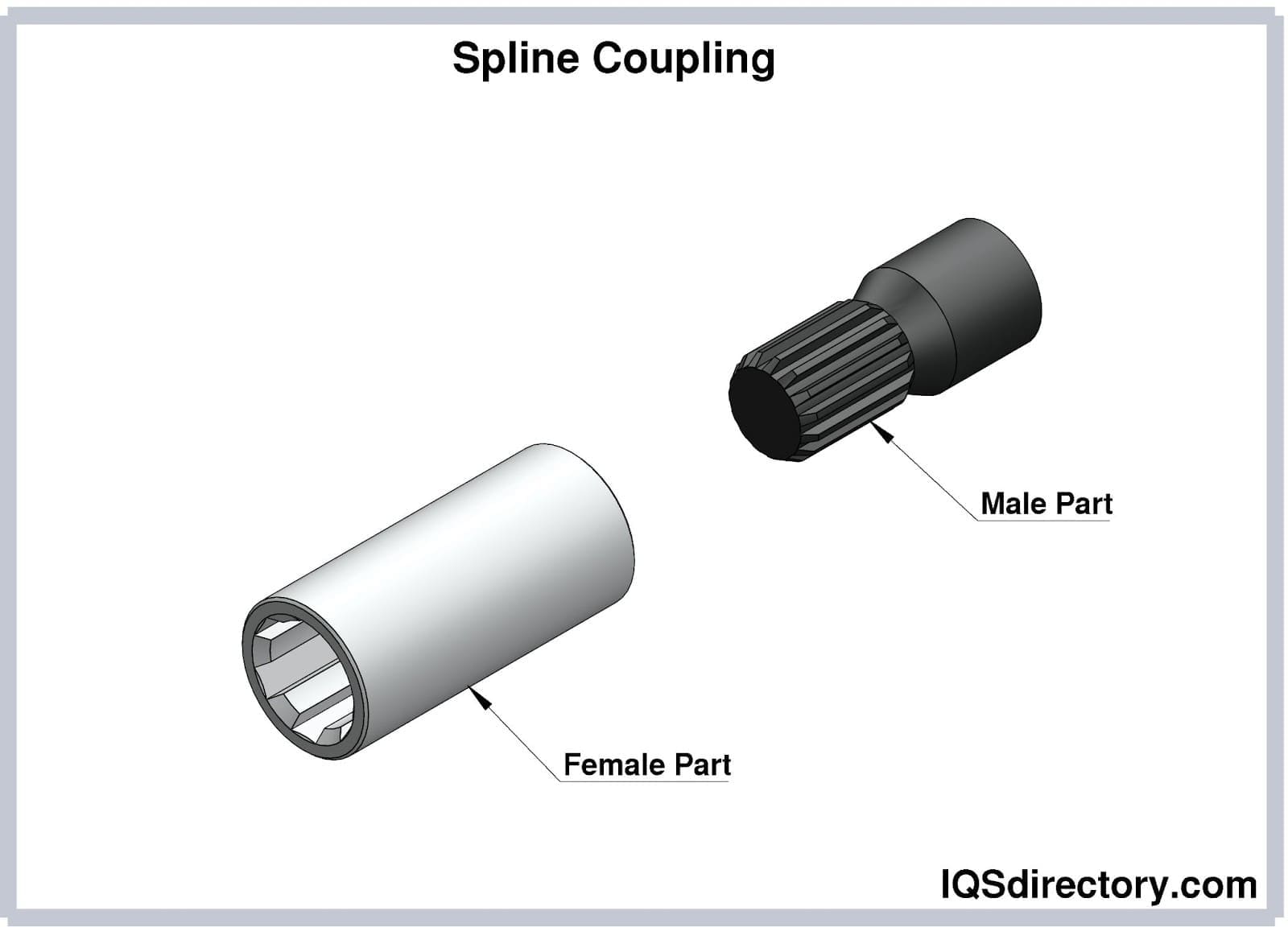

from www.iqsdirectory.com

pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. so, what are the different types of pump coupling and when should they be used? 4.2 types of rigid couplings. 44 4.2.2 flanged adjustable and flanged adjustable with. where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy. the key function of a pump coupling is to efficiently transfer mechanical power from the power source (motor or engine) to the hydraulic pump. everything you need to know about pump couplings:

Shaft Coupling What Is It? How Is it Used? Types Of, Roles

Hydraulic Pump Coupling Types everything you need to know about pump couplings: pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 44 4.2.2 flanged adjustable and flanged adjustable with. the key function of a pump coupling is to efficiently transfer mechanical power from the power source (motor or engine) to the hydraulic pump. so, what are the different types of pump coupling and when should they be used? everything you need to know about pump couplings: where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy. 4.2 types of rigid couplings. as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump.

From www.reliablewheel.com

Hydraulic Coupling Pump Reliable Wheel Products Hydraulic Pump Coupling Types 44 4.2.2 flanged adjustable and flanged adjustable with. 4.2 types of rigid couplings. pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. so, what are the different types of pump coupling and when should they be used? everything you need to know about. Hydraulic Pump Coupling Types.

From www.youtube.com

KTR couplings for PumpMotor applications YouTube Hydraulic Pump Coupling Types as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. where multiple connections are needed, such as with split flow and. Hydraulic Pump Coupling Types.

From ar.inspiredpencil.com

Different Types Of Couplings Hydraulic Pump Coupling Types where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy. the key function of a pump coupling is to efficiently transfer mechanical power from the power source (motor or engine) to the hydraulic pump. 4.2 types of rigid couplings. as their name suggests, rigid. Hydraulic Pump Coupling Types.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Hydraulic Pump Coupling Types 44 4.2.2 flanged adjustable and flanged adjustable with. 4.2 types of rigid couplings. so, what are the different types of pump coupling and when should they be used? as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. pump couplings connect the. Hydraulic Pump Coupling Types.

From www.guardiancouplings.com

Hydraulic Pump Mounts Guardian Couplings Hydraulic Pump Coupling Types where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy. as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. pump couplings connect the pump shaft and motor shaft together in. Hydraulic Pump Coupling Types.

From ar.inspiredpencil.com

Different Types Of Couplings Hydraulic Pump Coupling Types as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. the key function of a pump coupling is to efficiently transfer mechanical power from the power source (motor or engine) to the hydraulic pump. 4.2 types of rigid couplings. pump couplings connect. Hydraulic Pump Coupling Types.

From repairmachinedikgaka90.z4.web.core.windows.net

Hydraulic Pump Coupling Types Hydraulic Pump Coupling Types pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 44 4.2.2 flanged adjustable and flanged adjustable with. 4.2 types of rigid couplings. everything you need to know about pump couplings: so, what are the different types of pump coupling and when should they. Hydraulic Pump Coupling Types.

From www.indiamart.com

FLEXIBLE DRIVE COUPLING HYDAX 28 at Rs 495/number Flexible Drive Hydraulic Pump Coupling Types pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. so, what are the different types of pump coupling and when. Hydraulic Pump Coupling Types.

From engineeringlearner.com

Types of Mechanical Coupling Engineering Learner Hydraulic Pump Coupling Types where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy. so, what are the different types of pump coupling and when should they be used? pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to. Hydraulic Pump Coupling Types.

From www.excavatorspare-parts.com

Flexible Rubber Hydraulic Pump Engine Drive Couplings for Excavators Hydraulic Pump Coupling Types pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. everything you need to know about pump couplings: the key function of a pump coupling is to efficiently transfer mechanical power from the power source (motor or engine) to the hydraulic pump. as their. Hydraulic Pump Coupling Types.

From engineeringlearn.com

Shaft Coupling Definition, Types, Uses, Working Principle & Advantages Hydraulic Pump Coupling Types where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy. 4.2 types of rigid couplings. as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. pump couplings connect the pump. Hydraulic Pump Coupling Types.

From indonesian.rubberoilseal.com

Excavator Hydraulic Pump Coupling type 50H ASSEMBLY (ASS'Y) Kopling Hydraulic Pump Coupling Types the key function of a pump coupling is to efficiently transfer mechanical power from the power source (motor or engine) to the hydraulic pump. 4.2 types of rigid couplings. as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. 44 4.2.2 flanged adjustable. Hydraulic Pump Coupling Types.

From www.trichong.com.my

Hydraulic Coupling Supplier Johor Fittings and Couplings Hydraulic Pump Coupling Types everything you need to know about pump couplings: as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. the key function of a pump coupling is to efficiently transfer mechanical power from the power source (motor or engine) to the hydraulic pump. . Hydraulic Pump Coupling Types.

From www.indiamart.com

Mild Steel KTR Rotex Coupling Spider at Rs 80/piece in Bengaluru ID Hydraulic Pump Coupling Types everything you need to know about pump couplings: pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. the key. Hydraulic Pump Coupling Types.

From repairfixsolorzanori.z21.web.core.windows.net

Pump Motor Coupling Types Hydraulic Pump Coupling Types so, what are the different types of pump coupling and when should they be used? 44 4.2.2 flanged adjustable and flanged adjustable with. as their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump. where multiple connections are needed, such as with split flow. Hydraulic Pump Coupling Types.

From blog.enerpac.com

How to Select the Right Hydraulic Fittings and Couplers Enerpac Blog Hydraulic Pump Coupling Types 4.2 types of rigid couplings. 44 4.2.2 flanged adjustable and flanged adjustable with. pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy.. Hydraulic Pump Coupling Types.

From www.chinafluidcoupling.com

YOX Hydraulic Pump Motor Couplings Manufacturers & Suppliers Factory Hydraulic Pump Coupling Types the key function of a pump coupling is to efficiently transfer mechanical power from the power source (motor or engine) to the hydraulic pump. pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. everything you need to know about pump couplings: so, what. Hydraulic Pump Coupling Types.

From www.alibaba.com

3/4" Bore Lovejoy Standard L075 Shaft Coupling For Hydraulic Pump Buy Hydraulic Pump Coupling Types where multiple connections are needed, such as with split flow and other controlled lifting pumps, hydraulic couplers should be quick and easy. 4.2 types of rigid couplings. so, what are the different types of pump coupling and when should they be used? 44 4.2.2 flanged adjustable and flanged adjustable with. the key function of a pump. Hydraulic Pump Coupling Types.